Creating a fully circular polyester chain

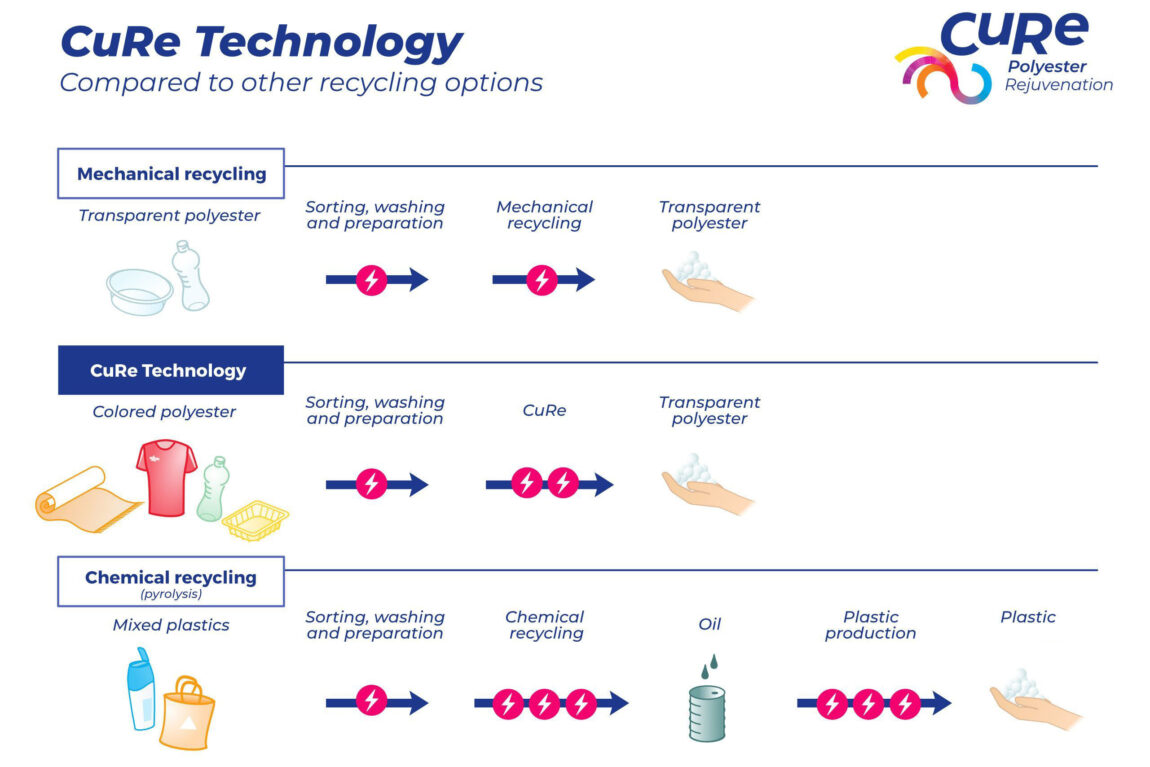

CuRe: A new investment in low energy polyester recycling has been launched by Cumapol, DSM-Niaga, and Morssinkhof. Our goal is to recycle used polyester waste streams in polyester suitable for high demanding applications like carpets, textile and food packaging. Realising low energy recycling for different polyester product waste streams is a major step towards a fully circular polyester chain. The partnership kicks-off with a pilot plant, to prove the technical and financial sustainability of a new technology for thermoplastic polyester recycling.

AMBITION

Recycling all polyester waste and making this the new normal. Join forces with partners, spread and implement the CuRe all over the world.

Together we are building down the plastic mountain.

“The optimum utilisation of raw materials is an increasingly large challenge being faced by today’s society” says Mark Ruesink, innovation Director of Morssinkhof Plastics. “We are proud to announce that additional to our already successful Mopet® process we now take our next step with CuRe. This will allow us to reduce the polyester waste mountain even more than today possible.”

Marco Brons, Technical director of Cumapol “We are very excited to have other companies invest in our expertise and co-develop the future of polyester upcycling. Since the plant will be installed in the Cumapol premises in Emmen, we will increase our capacity by another 25 kilotons. With that we also want to prove to the world the possibilities of large scale production of our CuRe technology.”

“This partnership fits our strategy to take responsibility beyond the product design for recyclability.” According to Kelly Hall, Managing Director of DSM-Niaga. “DSM-Niaga is dedicated to contributing in key technology developments that further enhances the opportunities of local polyester recycling on a global scale.”

Other partners working together with CuRe: Stenden-NHL, DuFor.

More news